Groundwater Wells 101

water well(wĕl) n.A water well is a hole, shaft, or excavation used for the purpose of extracting groundwater from the subsurface.

The general design of a well has two objectives:

Find adequate water supply that can be pumped at an adequate rate with adequate water quality.

Protect the aquifer from surface contaminates.

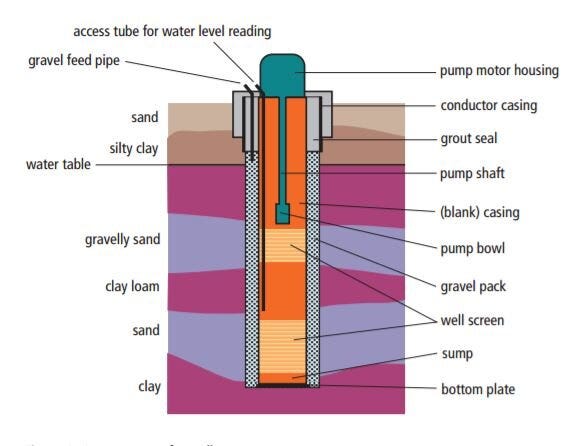

Here's the general concept for well completions. The

conductor casing (n. piece of large-diameter pipe)

is installed first-- it's a short length of pipe that provides extra protection against the borehole walls from caving in around the drill bit as we advance into the ground. It's only needed for the top 20-40 ft or so... after that the

overburden (n. dirt on top of the dirt)

has enough pressure to support drilling activities. Think of it like Jenga: the bottom pieces are easier to pull out without altering the structure of the puzzle because there's more weight on those pieces.

The rest of the hole is then drilled down to depth. A pilot hole is usually drilled first and then the hole is

reamed (v. drilled out with a bigger bit)

. We construct the well by attaching pieces of pipe from bottom to top, lowering the well "string" into the hole as we go. The practice is to "hang" the well from the ground surface, on top of the conductor casing, instead of letting it sit on the bottom of the

borehole (n. wellbore, hole in the ground)

. This way we can make sure the well is

plumb (adv. vertically hanging)

within the designed tolerance. As they are drilling, the driller's use a gyroscopic tool to check plumbness and alignment.

My job as the engineer on site is to make sure these are being drilled and installed properly, everyone is being safe, and to

log (v. identify & write down)

the geological characteristics of the

soil cuttings (n. bits of dirt cut up by the drill bit)

.

The bottom-most piece is a

sump (n. pipe attached to the bottom to catch any material that will come in through the screen).

Ears get welded onto the sides of the sump to hang the piece so that the screen can be welded on next.

The screen is installed on top of the sump, "screening" it in the aquifer that is selected for water supply. You'll notice in the graphic above, the screen is placed in the sand unit which produces more water than clay because sand has larger, connected pore spaces for water to flow through.

After screen installation, the rest of the pipe is welded on piece-by-piece. Each piece gets more ears for hanging. Generally,

centralizers

(n. funny looking things that help keep the casing string in the center of the borehole; see below)

will be installed.

Though I'm not totally convinced that centralizers do a whole lot, the purpose is to keep the well string straight so that no

bridging (v. when sand gets caught up and leaves large unfilled space)

occurs.

Now the casing is in the well, but there's still a huge hole around the well that surface contaminants, animals, or random sharpies clipped to my safety vest can fall into. We also want to make sure we've set material around the screen that is conducive to pulling in water, filtering fine materials in the process.

A rule of thumb is for a gravel pack (think, large sand) to be 10% smaller than the screen. That means, we intentionally want 10% of the pack to come through the screen. It's important to

develop (v. pushing water in and out of the formation through the well to settle the gravel pack and to pull fine sediments/drilling fluid out of the well; see featured image at top)

the well before it's placed into production so that the supply water isn't sandy. A well designed (and developed) well will increase the amount of water it can yield and extend the pump life.

There are many methods for filling the

annulus

(n. space between the borehole and casing)

. Two common ones are to pour the sand in from a giant bag or to use a tremie pipe. The same methods are applicable to installing a small clay plug on top of the sand and the grout which is placed on top of the

clay. Grouting is important as a seal to prevent cross-contamination between aquifers and to prevent surface contamination from draining down the outside of the well casing to the aquifer.

Tremie pipe

... A smaller diameter straw that goes between the well screen and the borehole.

The grout is pumped through the tremie and fills up the space with positive displacement--from the bottom up. I've seen drillers pull the tremie up as they go, especially in lifts. By stopping to check the depth occasionally, you can verify that the gravel pack is placed at the designed depth below ground surface. My job is to make sure this goes according the specifications that I stamped and signed for the design.

Well cementation is super important to help protect our groundwaters from surface contamination. If the cement doesn't seal the well correctly, contaminates can drain into the drinking water aquifer from the surface.

Now, we develop the well and run some pumping tests. Hooray! We completed a water well!

Working: Sending in final construction completion to TCEQ for a LT2 filtration project.

Listening: New Kiesza song. This amazing human being is my spirit animal.

Reading: Harry Potter y la piedra filosofal - anyone want to form a Spanish book club with me?

Sources:

,